Who are we ?

25 years of Service experience

We are a team of more than 20 years’ experience in the EMI and Thermal Management. From our French offices, we design and manufacture innovative products in both areas. Specializing in polymers and metals, we combine these materials and adapt manufacturing processes to offer new components, new products, new solutions:

WHAT YOU NEED.

Our fields of Actions

A full offer

Restart animation

Discover the animated video of our offer.

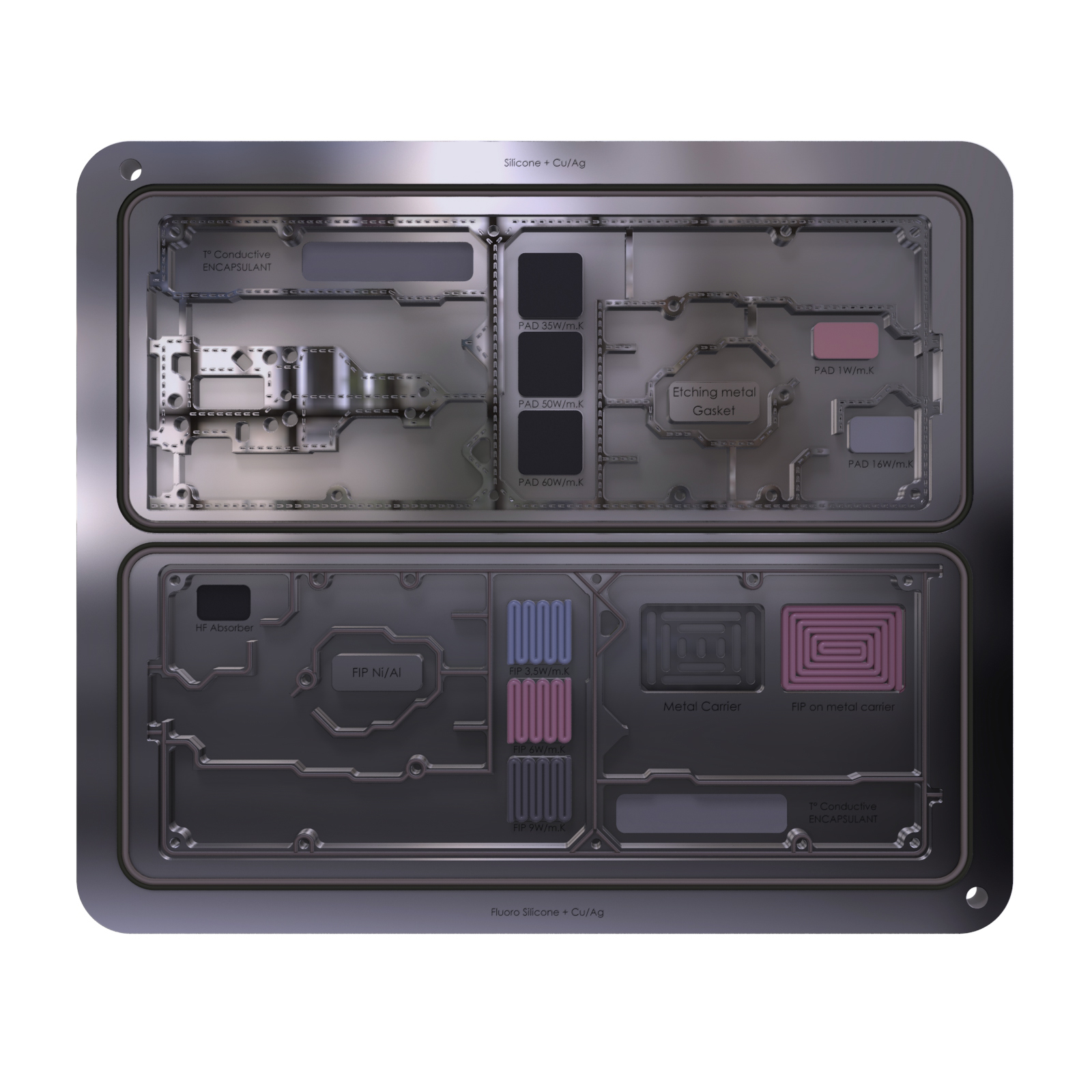

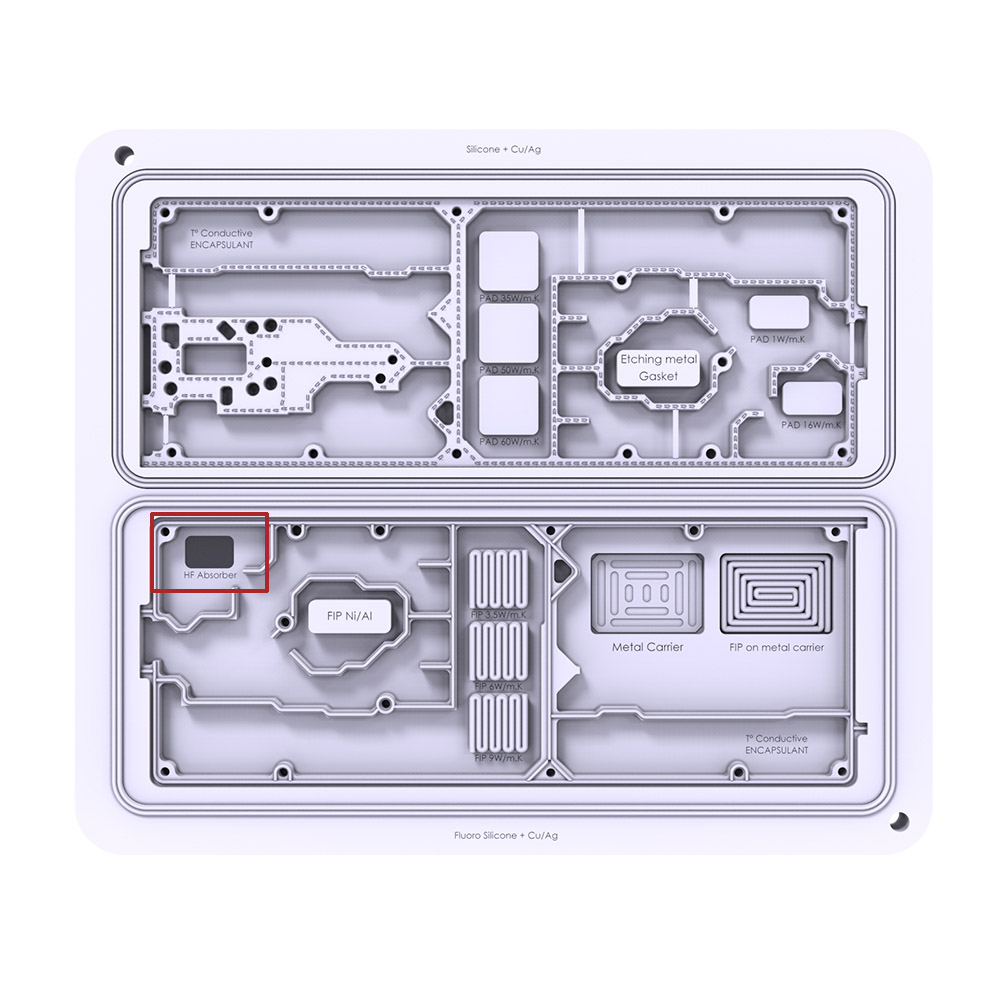

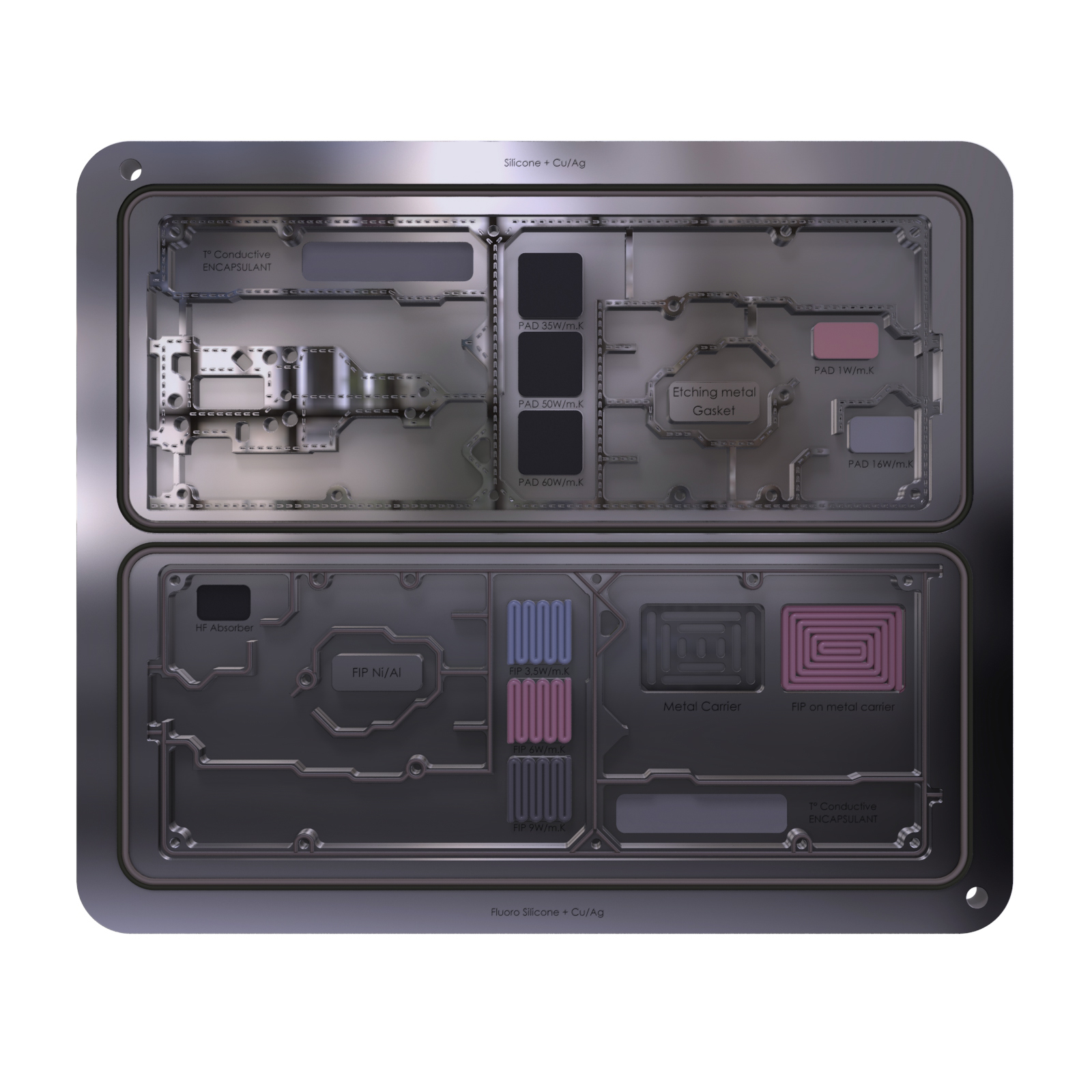

FULL OFFER

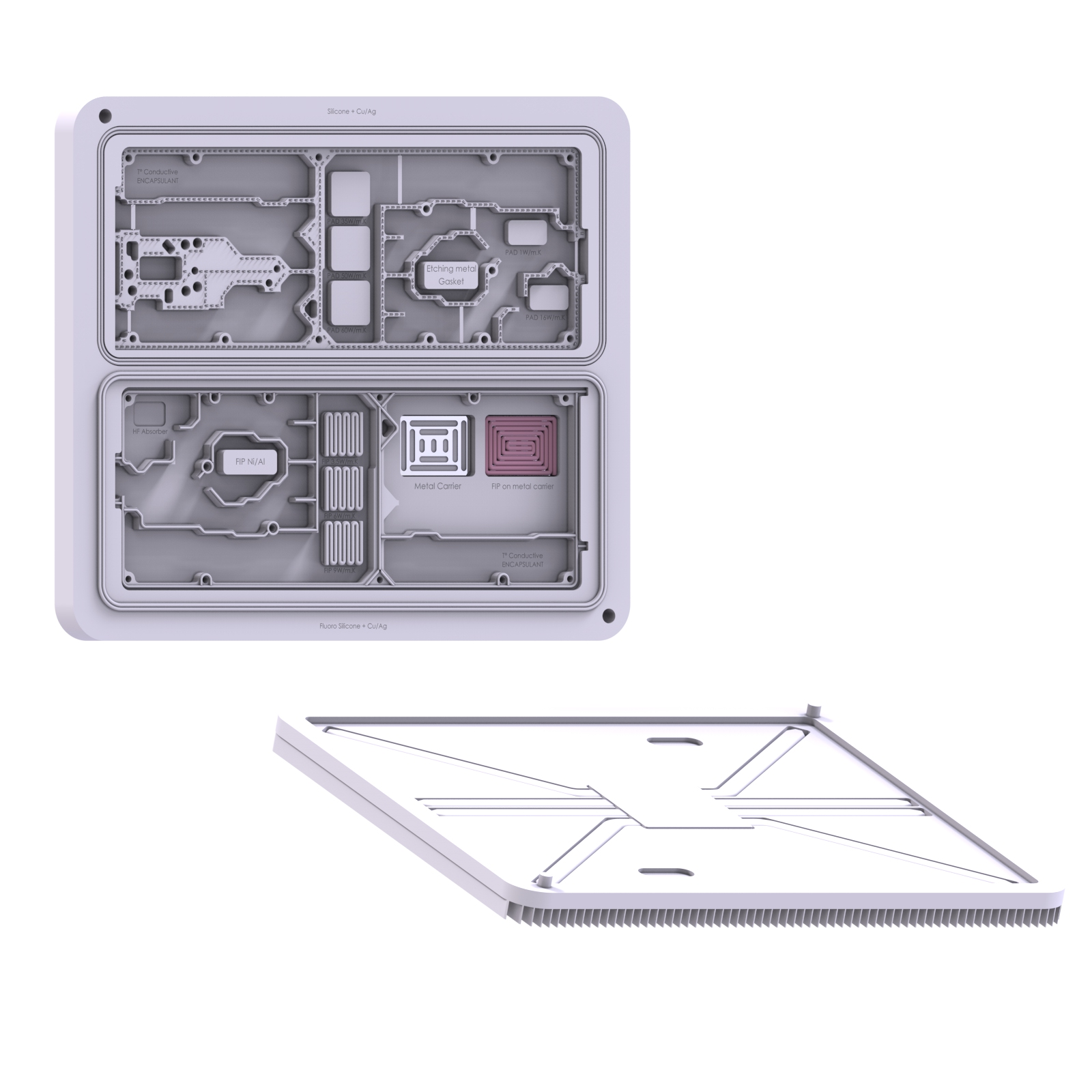

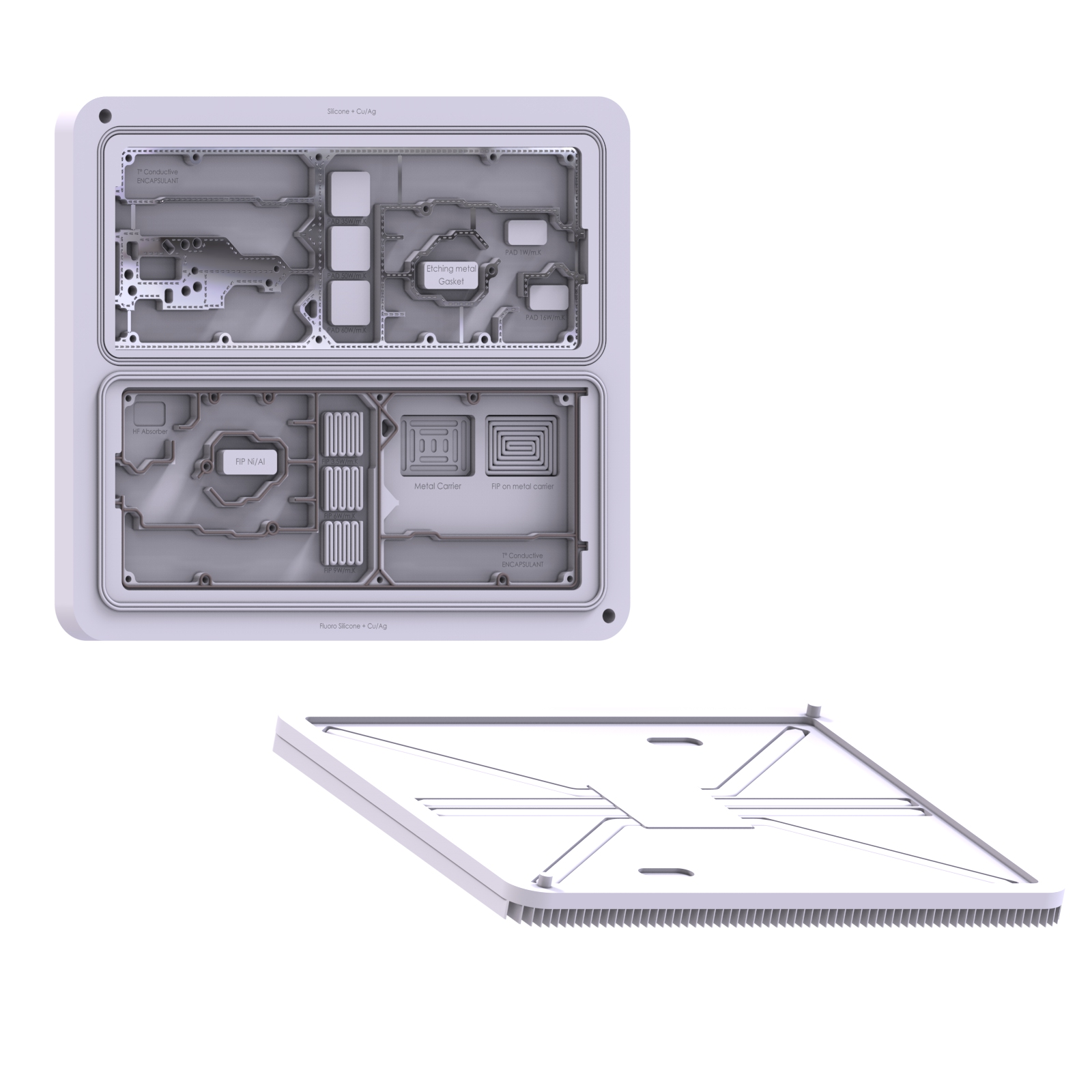

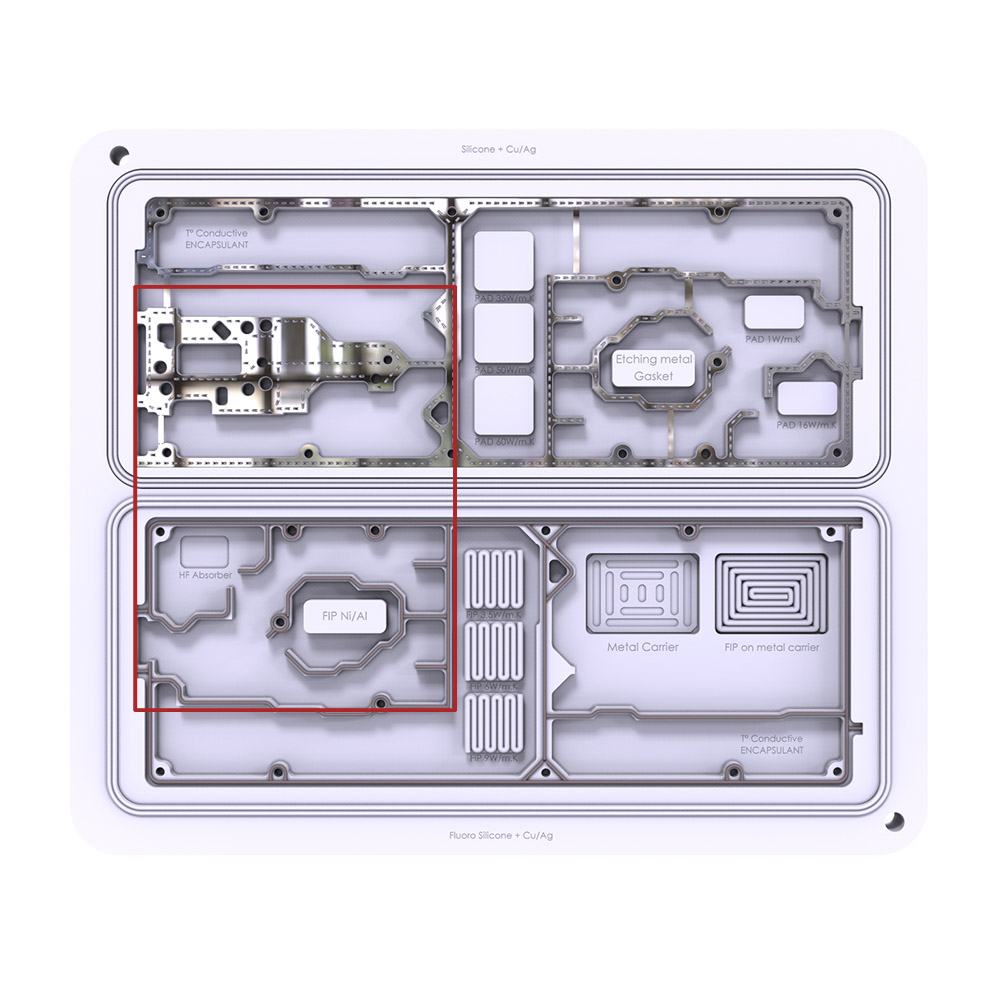

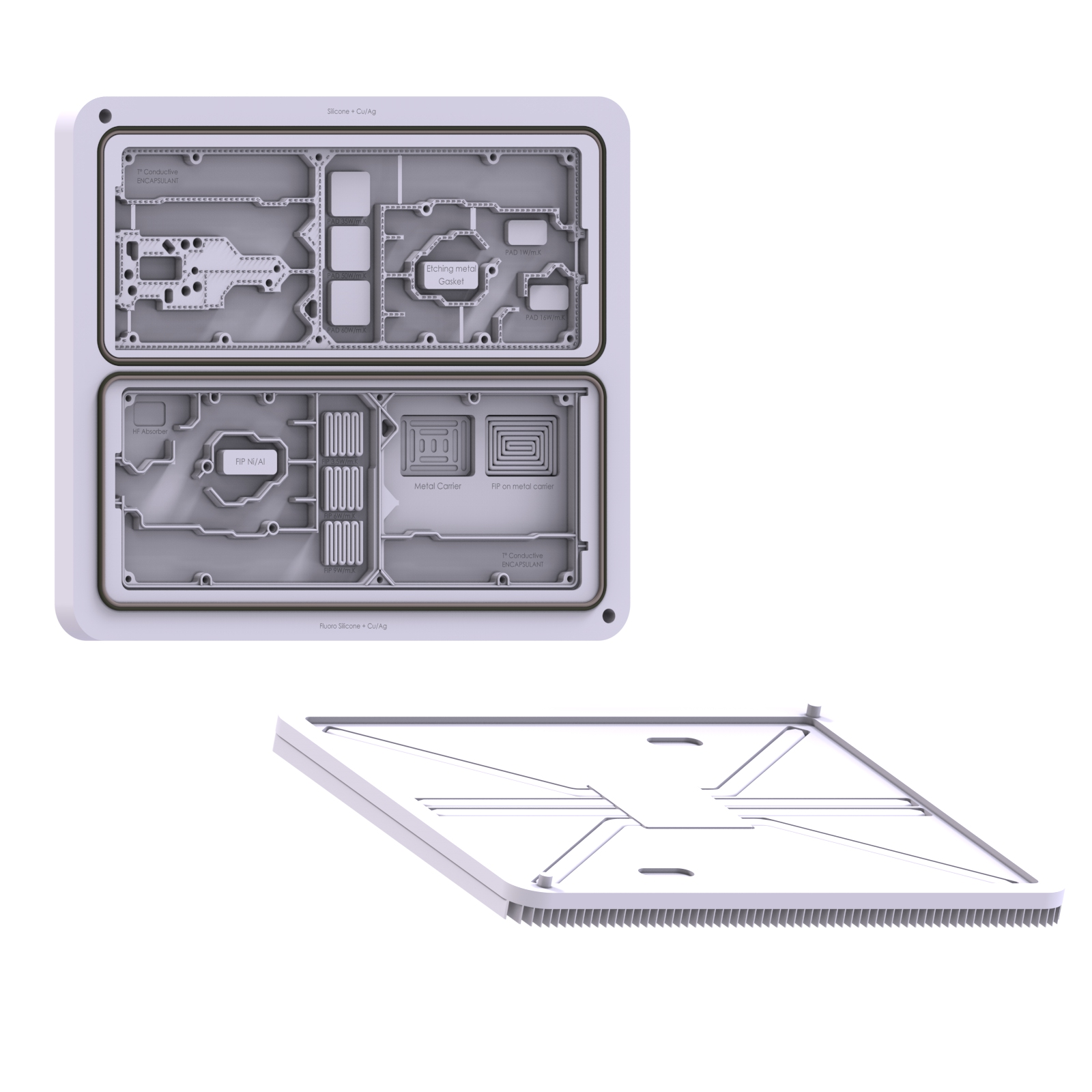

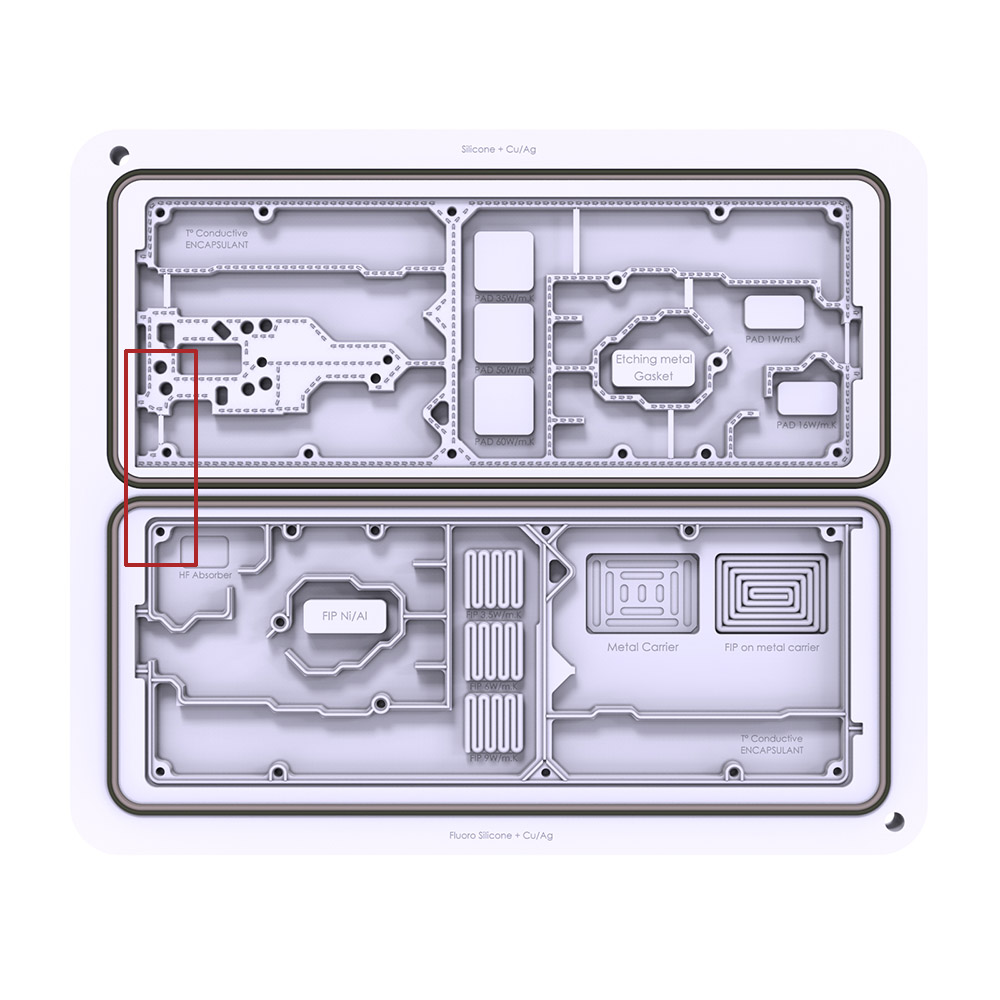

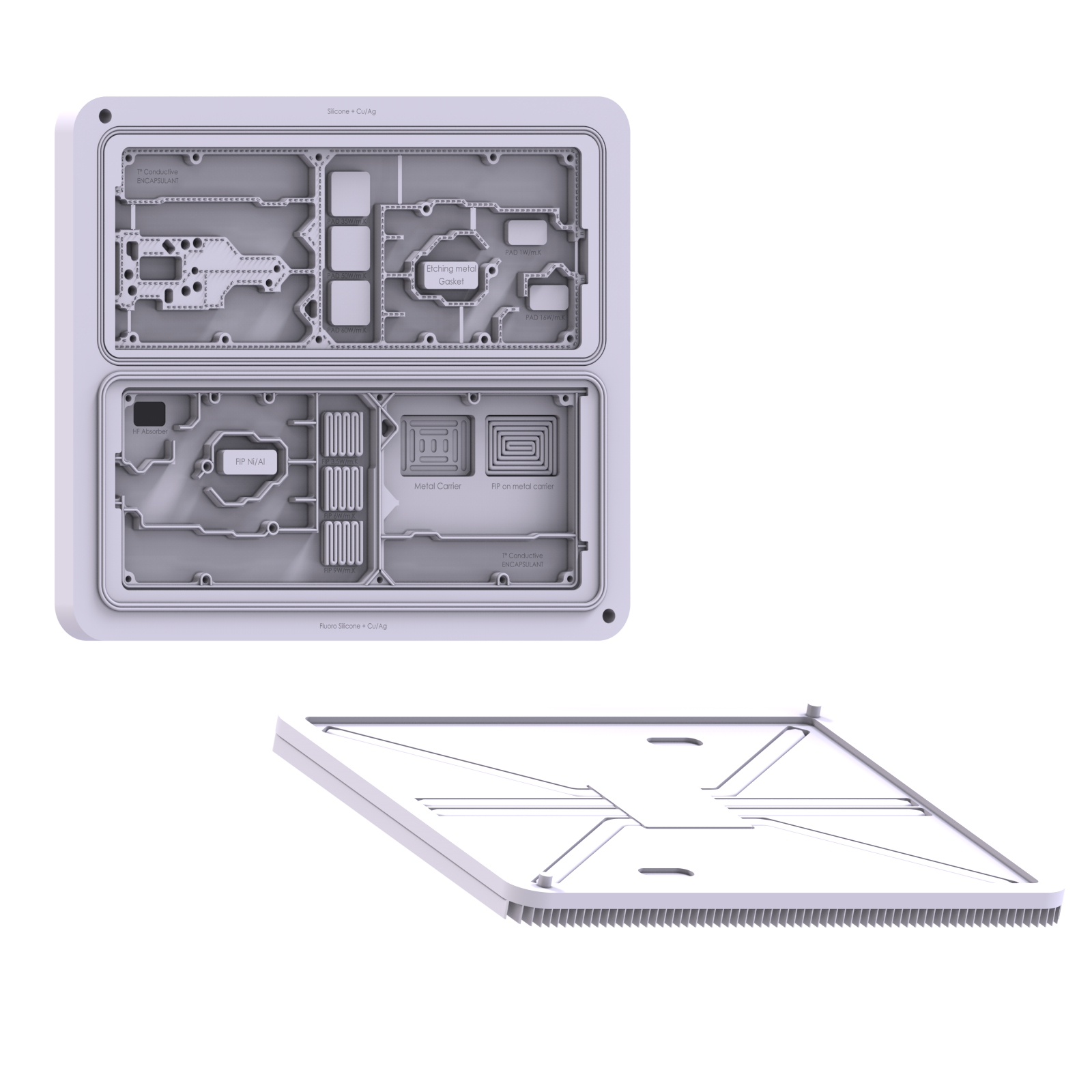

Our products and solutions cover the fields of EMI and Thermal Management. Our offer was expanded and increased in performance through the customer projects we have handled. This broad spectrum of solutions allows us to work in collaboration with our customers to identify with them the technical solutions that is innovative and the most adapted to their problems. We also develop sub-assemblies to simplify their flow and assembly costs.

Tell us about your project!

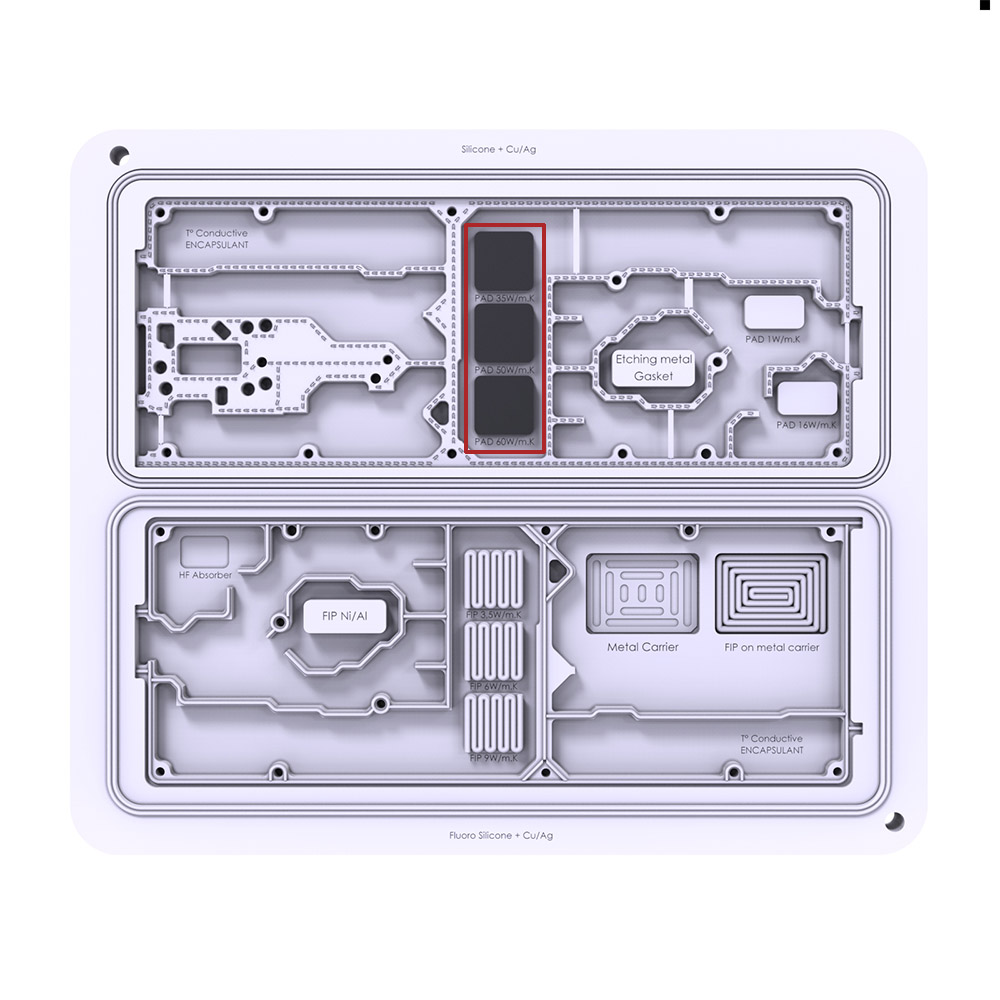

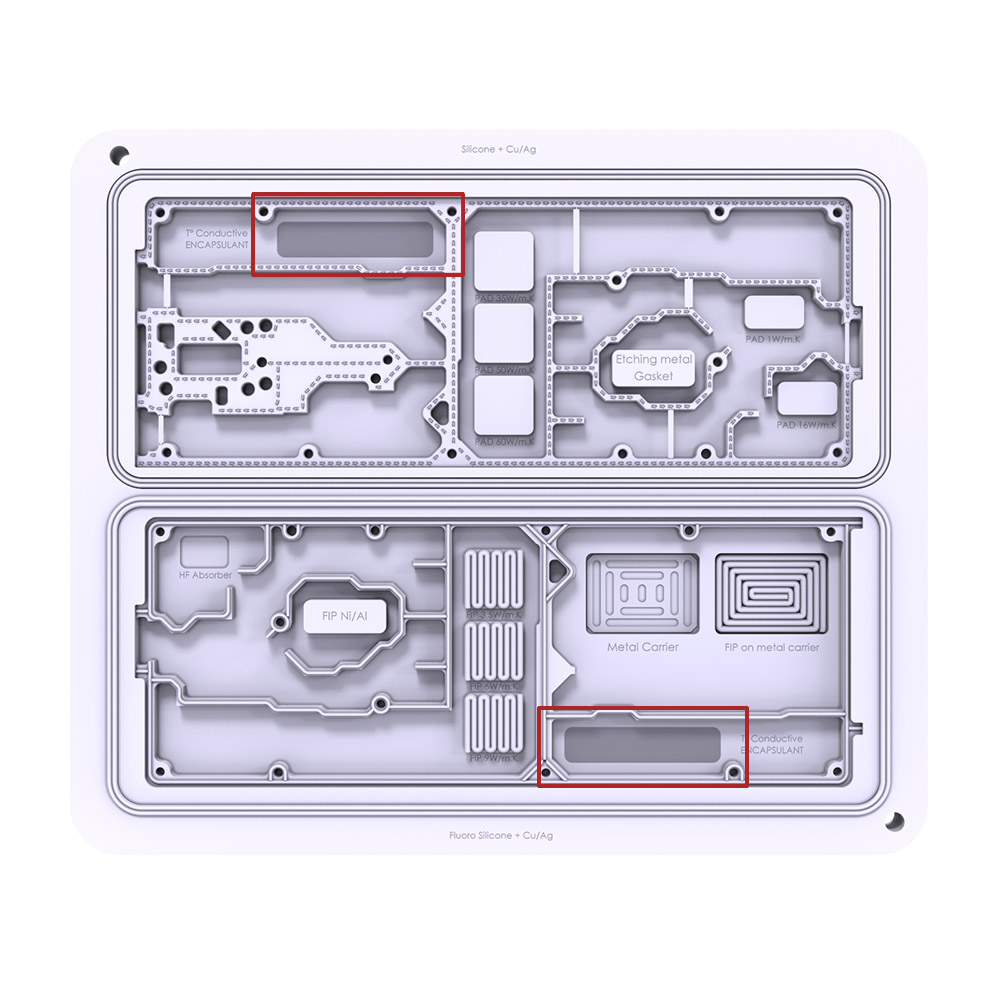

PREMIUM THERMAL PAD

Thermal conductivity: From 35 to 60W/mK

Hardness: From 20 to 50 Shore A

The DG-PTP is a silicone-based heat dissipating material loaded with carbon fibers aligned with each other. This material reveals a thermal conductivity of up to 60W/mK at only 10% compression.

DG-PTP is also electrically conductive.

We produce cut pieces according to your drawings to integrate perfectly with your design.

Consult us !

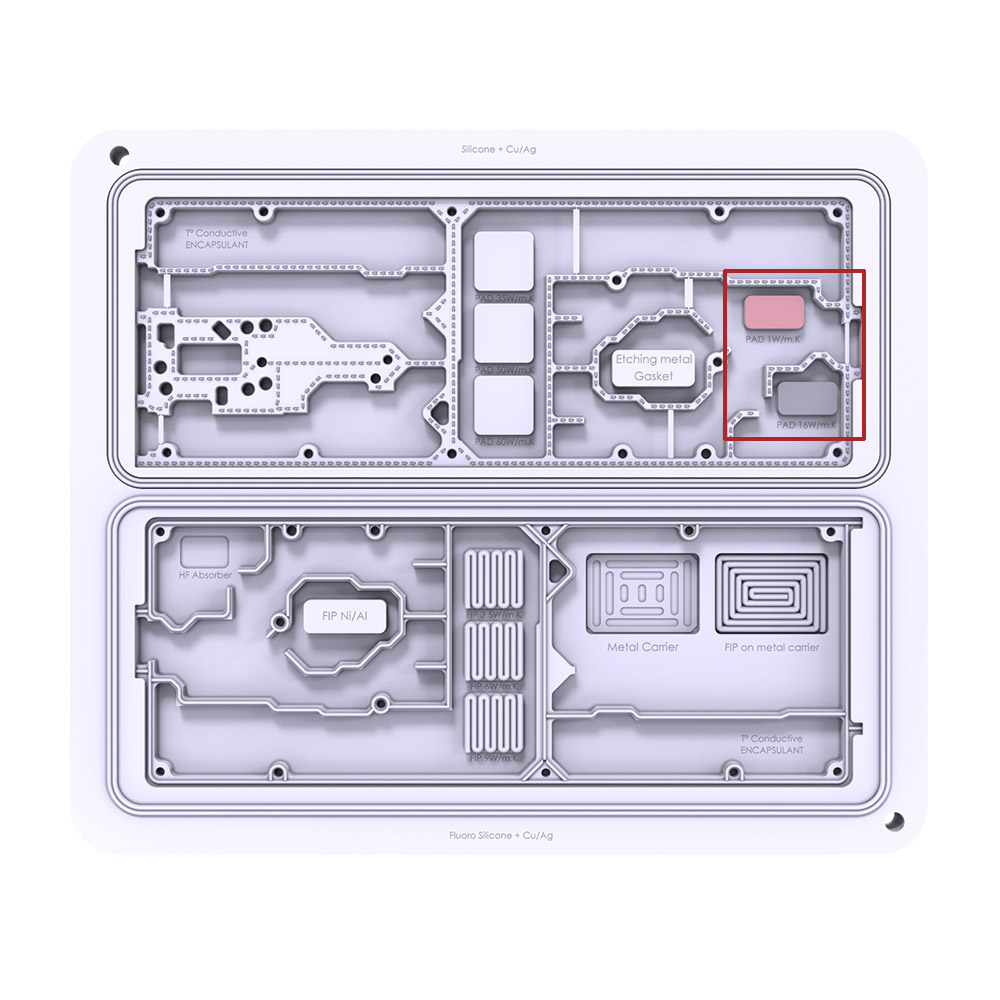

THERMAL PAD

Thermal conductivity: From 1.1 to 16W/mK

Compression @ 3mm, 60PSI: From 40 to 60%

The DG-PAD series is related to the “Thermal Interface Material“, often called TIM. It is a silicone-based heat dissipation material. Because of their flexibility, these thermal interfaces fill the gap between your electronic component and your heat drainage surface, while limiting the mechanical stress on your electronic components.

We advise you on the most suitable product for your configuration, and we manufacture quickly and reproducibly the shape corresponding to your equipment.

Contact us to learn more or request a sample!

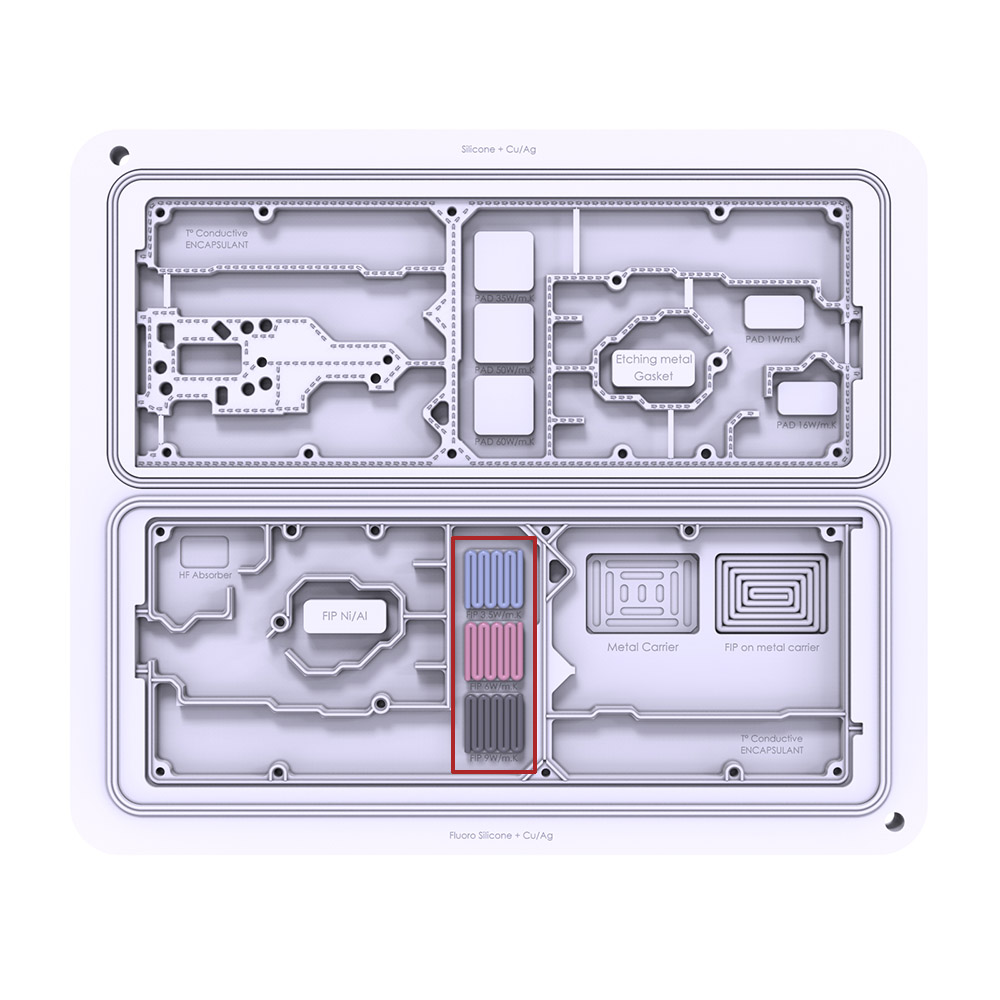

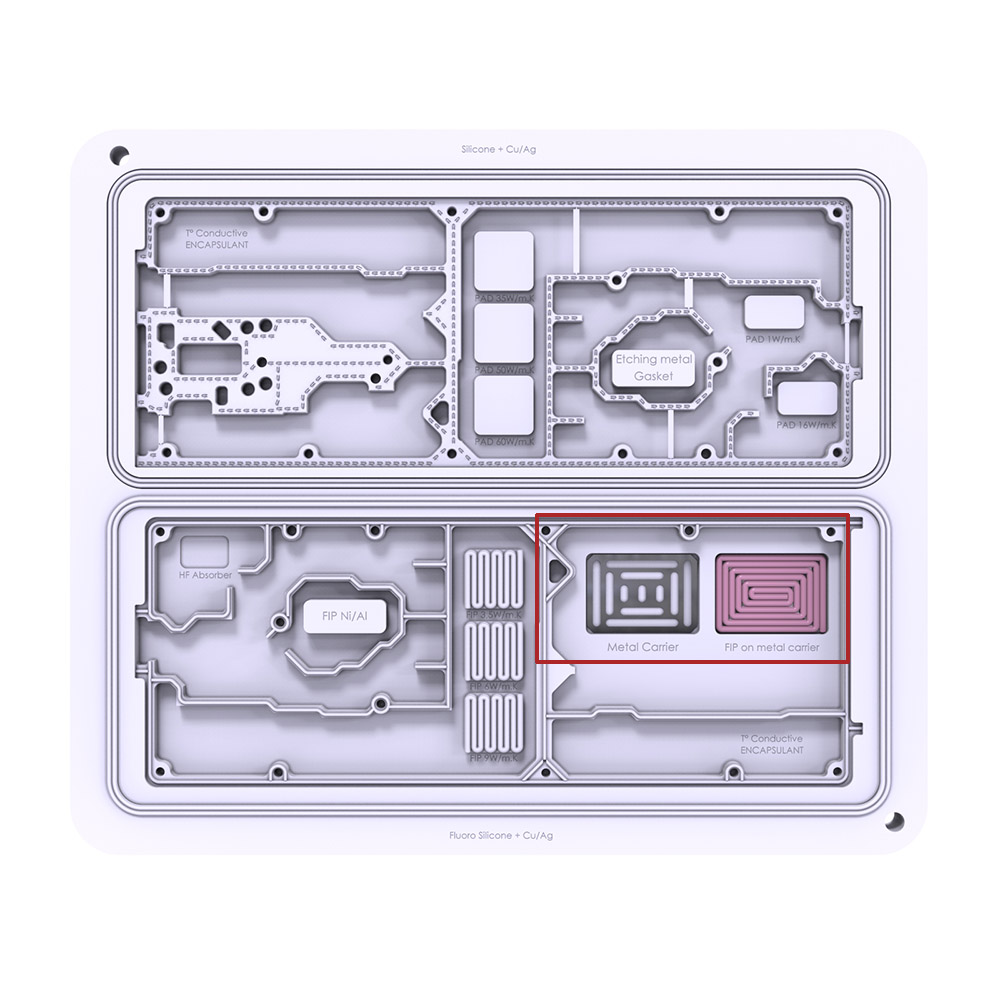

THERMAL DISPENSING FIP

Thermal conductivity: 3.5 to 9 W / mK

Thickness after removal: <0.5mm up to 5mm

DG-FIP is a Form-In-Place heat dissipation material. Because of its flexibility, this paste fills the slightest gap between your electronic component and your heat dissipation surface without mechanical stress.

Its thermal characteristics, among the best on the market, are adapted for your most compact and powerful electronic designs.

We also realize the delivery of our paste on your cards or mechanics. We can also manufacture your mechanics to optimize your supply chain.

Consult us!

THERMALLY CONDUCTIVE POTTING

Thermal conductivity: 1 to 2 W/mK

Hardness after polymerization: 80 shore 00

As a real alternative to Epoxy, our DG-TCSE series is a two-component sealant thermal conductive silicone. Its density, lower than epoxy, makes it a very interesting choice in applications where lightness is a technical argument.

Contact us to learn more or request a sample!

STAMPING

What we call “Stamping” is the process of stamping thin sheets of metal using a press of several tens or hundreds of tons, to obtain a piece cut flat or a geometry in 3D shape.

Very widely used for manufacturing metal grounding contacts in the field of connectivity, this process makes it possible to manufacture very large volumes of parts at competitive prices.

METAL / FIP GASKET

Mechanical compensation in height: 0.8 mm

Shielding: 90 dB

As soon as an EMI shielding gasket in your equipment is required between your mechanical cavities, you are facing 2 alternatives solutions: FIP-deposited gasket or metal gasket? We master both technologies and their respective advantages.

Tell us about your project and we will help you design and implement the most suitable solution.

dB-TWIN GASKET

Particles: Ag / Al; Ni / Al; Ag / Cu; Ag / glass

Shielding Efficiency (dB): 80 to 110 dB

Hardness (Shore A): 50 to 70 shore A

DB-TWIN conductive gaskets are coextruded gaskets. They are designed to fulfill the IP function and the EMI function in a single product, which improves the footprint and minimizes the cost of the IP and EMI functions in your design.

We adapt the profile of these gaskets to your mechanics for an optimal efficiency.

Their design allows efficient use in severe environments (salt spray, hydrocarbons …)

Contact us to learn more or request a sample!

EMI ABSORBER

Frequency (GHz): 1 to 35

Reflectivity (dB): 10 to 17 ~ 20

Our range of DB-ABS-N absorbers, Neoprene base, is specifically tuned for attenuation on a narrow band frequency range. This makes it more efficient in terms of signal intensity and environmental resistance.

Other ranges exist (RFID, etc …)

Contact us!

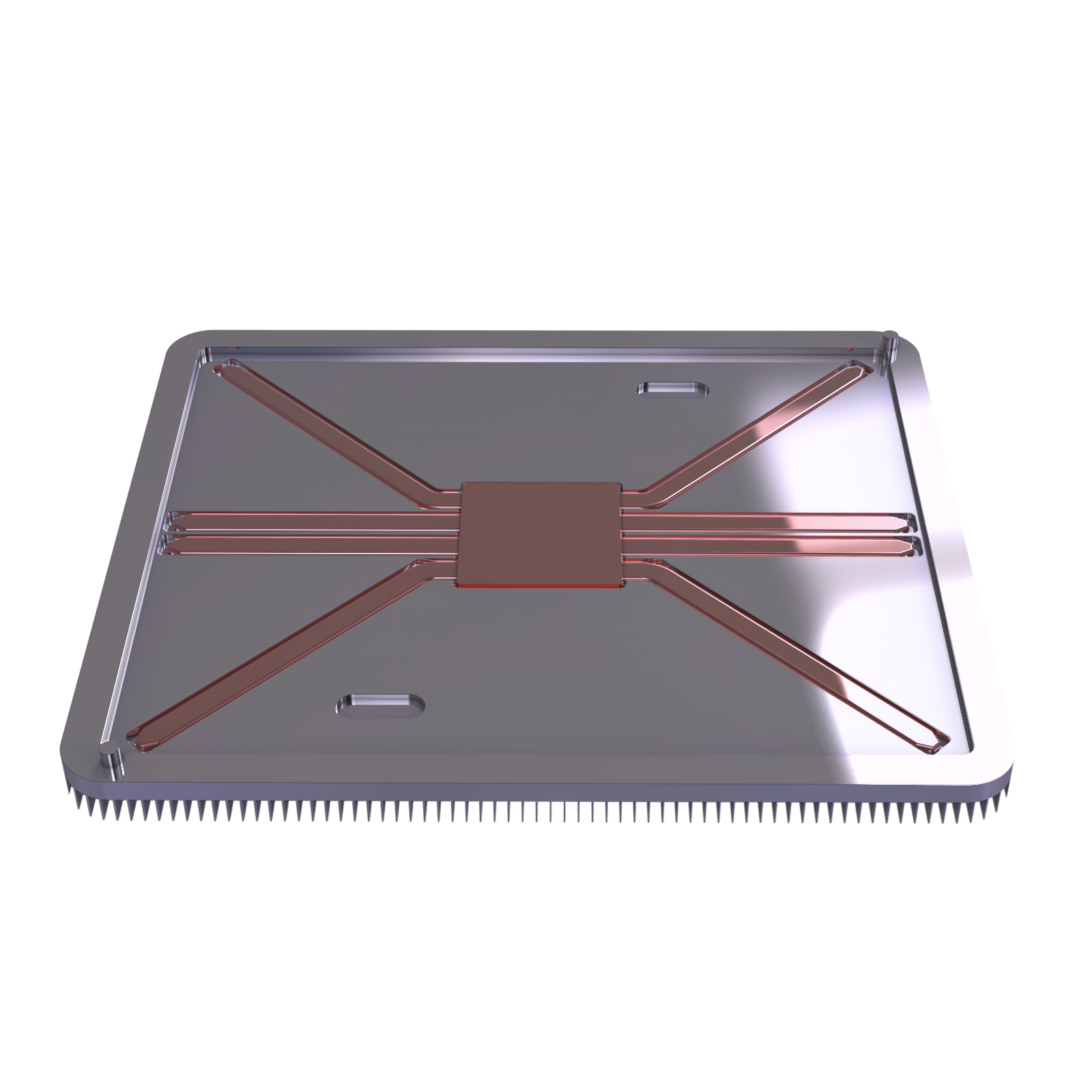

HEAT PIPE

Envelope materials: Cu, Al, Inox

Internal structure: mesh, fiber, sintering, grooving

The heat pipe is a heat transfer device that combines the principles of thermal conductivity and phase transition to efficiently transfer heat between two solid interfaces. It has a high thermal conductivity, it is 100 to 1000 times more efficient than a copper tube.

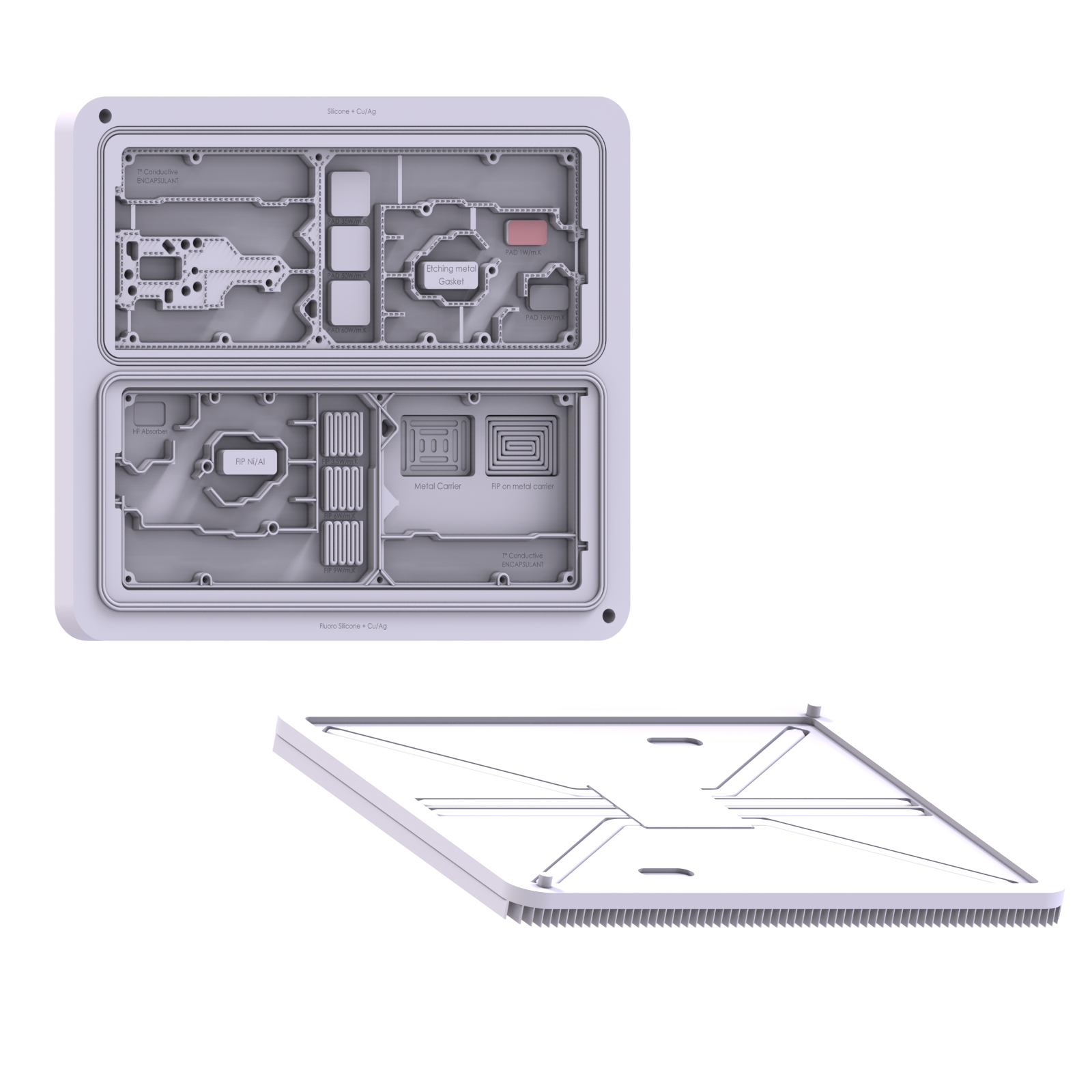

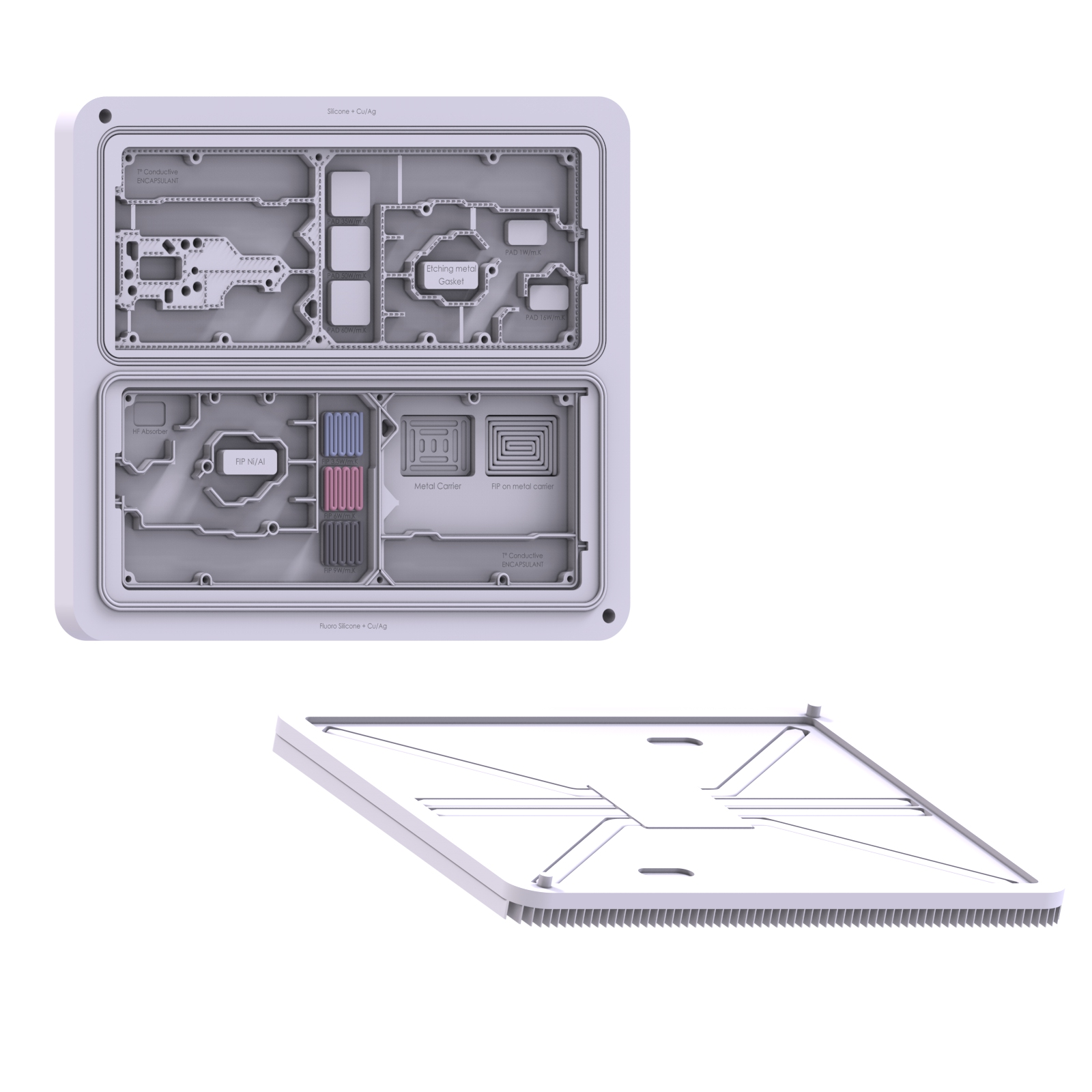

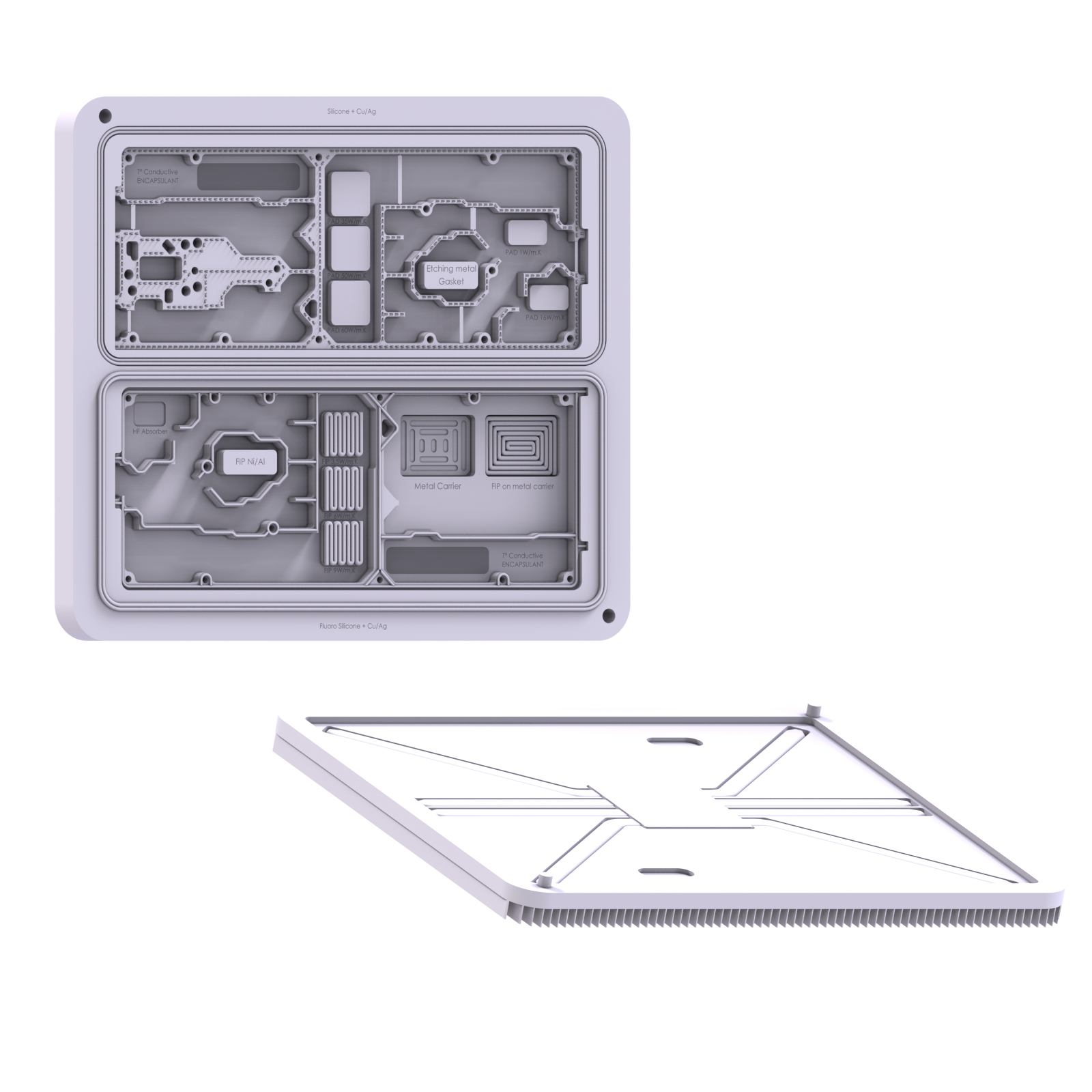

CNC

Machining tolerances: from +/- 0.125mm to +/- 0.025mm

Finishing: SurTec, Anodizing, Silver

Your mechanics do not only contain your PCB boards: they also help to fulfill the function of heat dissipation and / or electromagnetic shielding. We realize the machining of your Aluminum or Copper parts on 3/5/8 axes CNC machines, based on your 3D drawings. In addition, we assemble on it our EMI, IP and thermal components on request.

For more information contact us.

Your needs

We are here to meet your specific needs for a whole EMI and Thermal Solutions

Conception

A unique and personalized customer support to design the right solution for your existing environment.

Modeling

A quick realization of our solution on 2D and 3D drawings, for a good virtual integration in your equipment.

Prototyping

A rapid production of initial samples for validation.

Industrialization

A manufacturing and a delivery of parts and subassemblies throughout the life of your project, whatever your geographical location.

Our Assets

A sense of service made of excellence and agility

Efficiency

We understand your needs and their constraints. We have this global vision, composed with economic, technical and quality, which makes us your "unique contact ", flexible and responsive in the proposals and decision-making.

Reliability

Our in-process controls, the duplication of our production lines and sites, and the certification of our ISO 9001, 14001 and TS16949 production plants make us a reliable partner.

Relevance

We offer you the most adapted solutions to your problems, thanks to both our 25 years of expertise and the wideness of our product range.

Performance

Our range is focused on EMI and Thermal Management. It covers a wide choice, from the competitive component to the premium product with its exceptional performance.

Sustainability

With dB & DEGREES, you are certain to choose a product that will remain available throughout your program and its service period. No untimely 'catalog deletion' during the program.

We are at your disposal to carry out your projects.

A project ? A question ?

Your Environment

Answers to your problem

Telecoms Market

Study times are sometimes very short (a few months) and production volumes very high (> 100,000 pieces).

hyperfréquencies used in telecom infrastructures are becoming higher (D-band) and require extremely precise manufacturing processes (in the range of μm) and reproducible.

Our photo etching processes are particularly suited to this market, for designing and producing shielding gasket.

Embedded Market

In this market, the conditions of use are intense (resistance to impacts, vibrations), equipment must be compatible with hydrocarbon, UV … The materials resistance is a key point.

Our silicone base encapsulation solutions and our dB-TWIN co-extruded gaskets are particularly suitable for these demanding environments.

Industry Market

The variety of application cases ibn the industry market, particularly wide, requires a complete and adapted products and solutions offering: each area of the industry market has its own specificity. Examples: drones and their lightness problems, access control by RFID and read range constraints, data centers and industrial PCs with their increased thermal issues, ….

The widness of our range allows us, for each of their EMI and thermal problems, to respond with a suitable product, from the standard thermal pad, to the cold plate cooling system, and from the EMI shielding FIP gasket to the HF absorber.

Consumer Market

In this area, production volumes can be very high (up to several million pieces), with ever more competitive pricing searches (looking for annual productivity gains) and perfectly controlled logistics flows (consignment stocks).

Our phase change thermal interfaces are particularly suitable in this high volume market.

Medical Market

Annual volumes are quite low (a few hundred to a few thousand pieces), but they are compensated by a often long production life (7 to 10 years).

Environments are sometimes very sensitive, and the level of quality requirements is uncompromising.

Our heat dissipation mechanical solutions, from heat-sink to cold plate, are popular in these applications.

Military Market

In the Military Market, the projects lifetime are particularly long (sometimes more than 20 years). Our products are robust and functional over time.

The military environment is severe (NBC), with extreme weather conditions, salt fog type…

Our range of dB-Twin co-extruded shielding gaskets and DG-TCSE thermal encapsulation are particularly suitable in this market.